Science and tech-savvy community members help fight equipment shortages

UMass Dartmouth scientists and 3D printing enthusiasts are just some of the community members donating much-needed equipment to protect health workers during the coronavirus pandemic.

Hospitals all over the country are experiencing shortages of Personal Protective Equipment (PPE) as they gear up to fight the highly contagious virus — so Associate Professor of Bioengineering at UMass Dartmouth Tracie Ferreira and 3D printing hobbyist Nick Macedo are doing what they can to help out.

Ferreira said her lab donated 15 pairs of safety goggles and 3,000 gloves to Southcoast Health hospitals as part of a campus-wide effort.

Most university research experiments have been shut down and cell cultures frozen for the duration of the crisis, so the equipment is largely not being used.

“It’s certainly more important for everybody else right now, like medical staff,” she said. “Our experiments aren’t that important.”

All told, UMass Dartmouth’s science and facilities departments donated 119 N95 masks, 5,500 gloves, 300 shoe covers, and 35 face protectors to St. Luke’s Hospital in New Bedford, according to university spokesman Ryan Merrill.

“It was really kind of a big team effort, doing what we can to help the region,” he added. “That’s why we partnered with Southcoast Health — they’re going through a lot right now, so anything we can do to help.”

Merrill noted that the university hopes to donate any new supplies delivered during the crisis, but since everything is currently backordered, he has no idea when that will happen.

As for Ferreira, she said she wanted to let people know that the university cares about the community.

“It’s about doing what you can to make things for people a little bit better,” she said.

3D printing hobbyist Nick Macedo agreed with the sentiment.

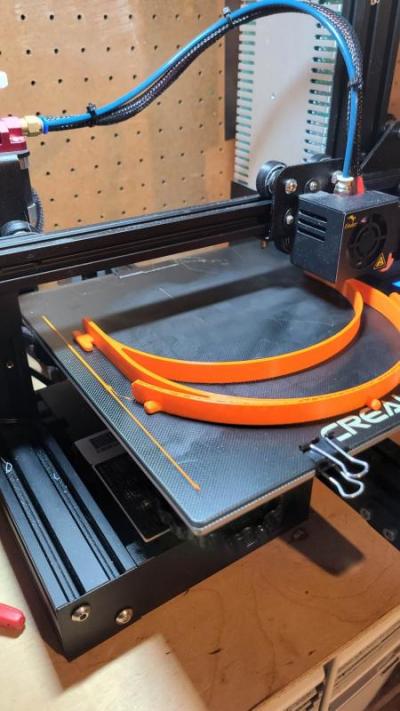

The Dartmouth resident said that he was laid off from a job in the trade show industry due to the pandemic, and has been making 3D-printed visors for plastic face shields since then.

“This gives me some way of keeping busy and supporting the healthcare workers on the front lines,” he said, adding that printing face shields “makes me feel like I'm contributing while being out of work.”

Macedo said that he saw online posts on 3D printing forums about making the visors, and “thought it was an amazing idea.”

So far, he has made about 20 visors from designs approved by the National Institutes of Health that are available online.

And it doesn’t take much in resources — each visor takes around five hours to make, and costs around $1 in filament, the plastic material that feeds into the printer.

He is expecting a delivery of clear acetate film that will clip into the visors to make the shields, which block airborne droplets from the faces of anyone wearing them.

Once complete, he said, he will give the first few face shields to family members who work in health care, before donating them to local hospitals.

“St. Luke's will be my first call when they are all assembled and ready to go,” he said.

“I plan to keep printing around the clock. It's not many but if everyone with a hobby printer at home contributes it could be tens of thousands of shields,” he added. “I will keep printing so long as I have money to buy filament and there is a need.”