Family-operated sawmill slices logs into potential projects

Jack Delano slices into a log at Joseph K. Delano Sawmill. The circular saw is about 50 inches across and has 40 teeth. BY SETH THOMAS

Jack Delano slices into a log at Joseph K. Delano Sawmill. The circular saw is about 50 inches across and has 40 teeth. BY SETH THOMAS Jack Delano manipulates a large crane arm to place logs onto a conveyor belt. BY SETH THOMAS

Jack Delano manipulates a large crane arm to place logs onto a conveyor belt. BY SETH THOMAS A bandsaw in the shed toward the back of the property makes finer cuts. BY SETH THOMAS

A bandsaw in the shed toward the back of the property makes finer cuts. BY SETH THOMAS Pieces with round edges are left around the sawmill. These pieces could be used for benches or tables or anything else a craftsmen could imagine. BY SETH THOMAS

Pieces with round edges are left around the sawmill. These pieces could be used for benches or tables or anything else a craftsmen could imagine. BY SETH THOMAS A large pile of wood chips at the sawmill. BY SETH THOMAS

A large pile of wood chips at the sawmill. BY SETH THOMAS The main shed of the sawmill. The pipes up top are used to funnel sawdust to a different part of the property. The dust is transported through the pipes with air pressure. BY SETH THOMAS

The main shed of the sawmill. The pipes up top are used to funnel sawdust to a different part of the property. The dust is transported through the pipes with air pressure. BY SETH THOMAS Jack Delano measures logs on the conveyor belt. BY SETH THOMAS

Jack Delano measures logs on the conveyor belt. BY SETH THOMAS Jack Delano sharpens the teeth of the large circular saw with a handheld device before cutting into logs. BY SETH THOMAS

Jack Delano sharpens the teeth of the large circular saw with a handheld device before cutting into logs. BY SETH THOMAS Jack Delano trims the bark off a log. BY SETH THOMAS

Jack Delano trims the bark off a log. BY SETH THOMAS Sawdust flies through the air as boards are cut from a log. BY SETH THOMAS

Sawdust flies through the air as boards are cut from a log. BY SETH THOMAS The sawmill is located on 156 Cross Road. BY SETH THOMAS

The sawmill is located on 156 Cross Road. BY SETH THOMAS Jack Delano slices into a log at Joseph K. Delano Sawmill. The circular saw is about 50 inches across and has 40 teeth. BY SETH THOMAS

Jack Delano slices into a log at Joseph K. Delano Sawmill. The circular saw is about 50 inches across and has 40 teeth. BY SETH THOMAS Jack Delano manipulates a large crane arm to place logs onto a conveyor belt. BY SETH THOMAS

Jack Delano manipulates a large crane arm to place logs onto a conveyor belt. BY SETH THOMAS A bandsaw in the shed toward the back of the property makes finer cuts. BY SETH THOMAS

A bandsaw in the shed toward the back of the property makes finer cuts. BY SETH THOMAS Pieces with round edges are left around the sawmill. These pieces could be used for benches or tables or anything else a craftsmen could imagine. BY SETH THOMAS

Pieces with round edges are left around the sawmill. These pieces could be used for benches or tables or anything else a craftsmen could imagine. BY SETH THOMAS A large pile of wood chips at the sawmill. BY SETH THOMAS

A large pile of wood chips at the sawmill. BY SETH THOMAS The main shed of the sawmill. The pipes up top are used to funnel sawdust to a different part of the property. The dust is transported through the pipes with air pressure. BY SETH THOMAS

The main shed of the sawmill. The pipes up top are used to funnel sawdust to a different part of the property. The dust is transported through the pipes with air pressure. BY SETH THOMAS Jack Delano measures logs on the conveyor belt. BY SETH THOMAS

Jack Delano measures logs on the conveyor belt. BY SETH THOMAS Jack Delano sharpens the teeth of the large circular saw with a handheld device before cutting into logs. BY SETH THOMAS

Jack Delano sharpens the teeth of the large circular saw with a handheld device before cutting into logs. BY SETH THOMAS Jack Delano trims the bark off a log. BY SETH THOMAS

Jack Delano trims the bark off a log. BY SETH THOMAS Sawdust flies through the air as boards are cut from a log. BY SETH THOMAS

Sawdust flies through the air as boards are cut from a log. BY SETH THOMAS The sawmill is located on 156 Cross Road. BY SETH THOMAS

The sawmill is located on 156 Cross Road. BY SETH THOMASWith a throw of a switch, the giant circular saw at the heart of Joseph K. Delano Sawmill rips through a tree trunk in minutes. It’s the first step in transforming a hefty log into boards, kindling and wood chips.

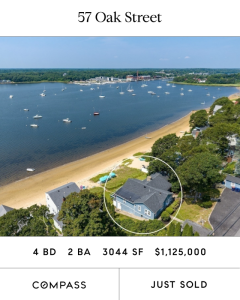

Owner Jack Delano said the mill has been in his family for generations. Established in 1922 by his grandfather, Joseph, the mill was originally situated where Wal-Mart is today. In 1940, it moved down the street to its location on 156 Cross Road.

Sawdust and planks of wood are piled high around the 2-acre property. The site is a hodge podge of sheds, heavy machinery and hidden treasures.

Delano said that his customers range from bigger industries, such as Eversource or local construction companies, to residents from around the area who wander through looking for irregular pieces of wood.

John Delano, Jack’s son who works at the mill, said that after making more deliberate cuts to produce things like tent poles and ramps for boats, sometimes the two are left with an extra plank that has potential for us in a side project.

“We have a lot of odd pieces,” said John. “You end up with some irregular pieces at the end of boards.”

For instance, in the back shed, a 3-inch piece of maple with rounded corners is propped up against the wall. He said something like that could make for a great mantlepiece. The mill’s Facebook page has several photos of furniture that customers have assembled with lumber lying around the property. John said that sometimes artists from UMass Dartmouth will drop by.

“The college is right up there, so they’re doing projects. They’re getting random things to make sculptures out of,” Jack said. “People from off the street can come and buy whatever.”

It all starts with logs about a foot-and-a-half wide. The main shed houses a circular saw, about 50-inches in circumference with 40 teeth. Each tooth is sharpened with an electric handheld device before slicing into a log. Depending on the condition of the wood, the blade could have to be sharpened every 45 minutes.

“You gotta sharpen it all the time and clean it. [Jack] is always sharpening it every few rotations,” said John.

After logs are delivered and piled near the main shed, Jack uses a metal grappling arm to lift the logs and position them on a conveyor belt. The arm is similar to the hooks found on the back of logging trucks and looks something like a crane from an arcade machine.

The logs are then positioned and locked onto a rolling carriage, which rides along a set of tracks so the log can be easily moved toward the blade and cut. To make sure that as little of the log is wasted as possible, air pressure vents sawdust through a metal pipe overhead, piling the dust nearby.

As Jack rotates the log and slices it into one-inch boards, John uses a long stick to clear debris from the area around the base of the blade.

From there, boards will be processed differently, and there’s a shed toward the back of the property that has equipment for finer adjustments, such as a bandsaw for precise cuts and a wood planer to smooth the tops of the boards.

A big draw is some of their smallest pieces, including kindling and stakes for gardening. But that’s only part of what Jack and John Delano have to offer.

“We make boards for fishing boats and stakes for snow work and gardens. We make wood products of all kinds,” said John. “We don’t waste too much here.”

For those interested in starting a new project, Joseph K. Delano Sawmill is located at 156 Cross Road. The mill is open Monday through Friday from 8 a.m. to 5 p.m. and on Saturdays from 8 a.m. to noon.